1. What Are the Uses of Tungsten-Copper Electrodes

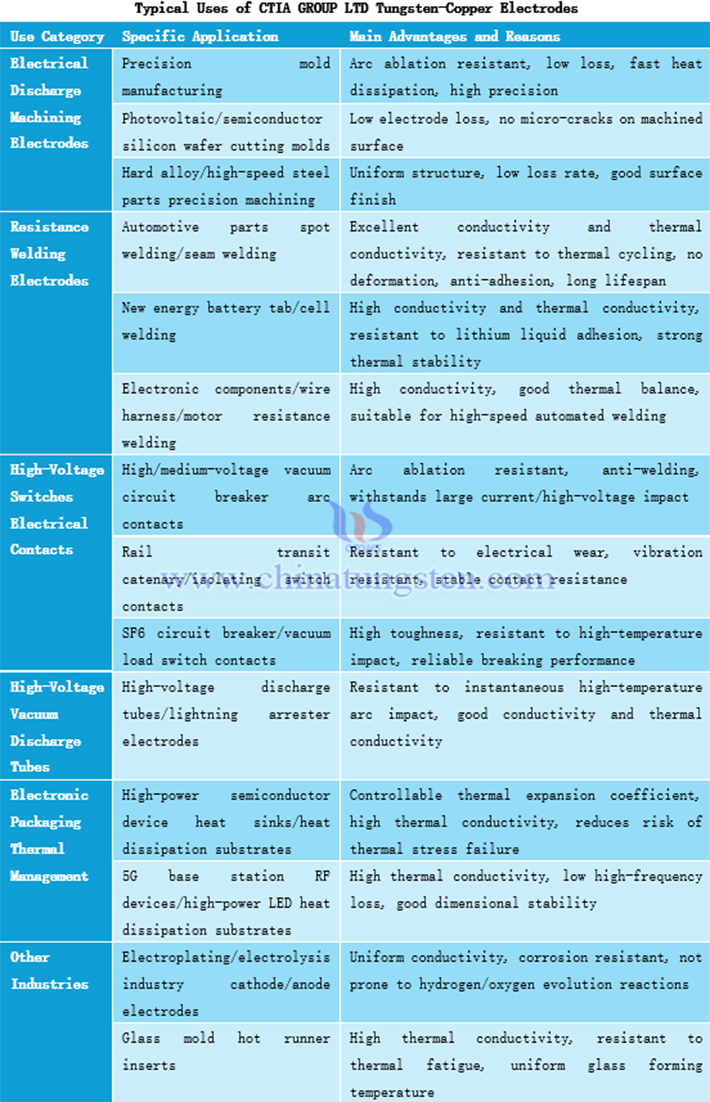

The uses of CTIA GROUP LTD tungsten-copper electrodes are extensive, covering electrical discharge machining, resistance welding, high-voltage switches/electrical contacts, high-voltage vacuum discharge tubes, electronic packaging/thermal management, and other industrial fields, fully combining tungsten's high melting point, arc ablation resistance, and high-temperature characteristics with copper's excellent electrical and thermal conductivity to achieve high-temperature, high-precision, and high-reliability applications. CTIA GROUP LTD and its parent company CTIA GROUP LTD have been deeply engaged in the tungsten-molybdenum products industry for nearly 30 years, specializing in flexible customization and global services for tungsten-molybdenum products, capable of custom processing various specifications, performance, sizes, and grades of tungsten-molybdenum products according to customer needs. For more information on tungsten-copper alloys, please visit the website: http://www.tungsten-copper.com/index.html. For any tungsten-copper electrode products, please contact CTIA GROUP LTD: sales@chinatungsten.com, 0592-5129595.

Typical Uses of CTIA GROUP LTD Tungsten-Copper Electrodes

CTIA GROUP LTD Tungsten-Copper Electrode Images

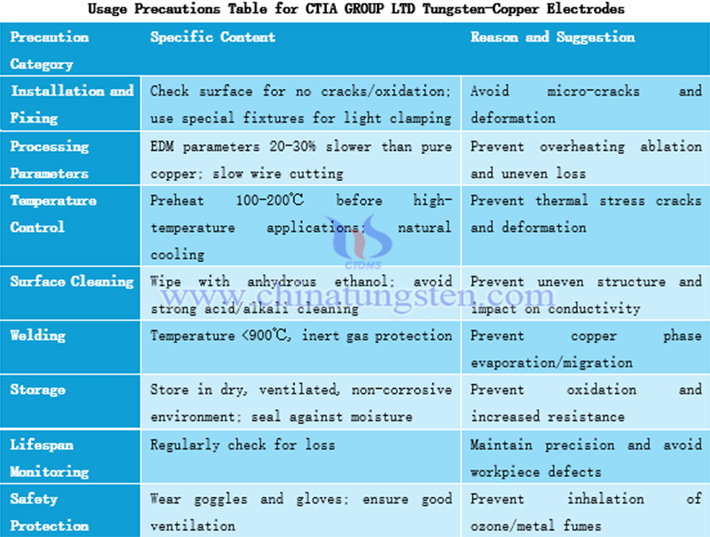

2. Usage Precautions for Tungsten-Copper Electrodes

Usage of tungsten-copper electrodes requires attention to installation precision, moderate parameters, gradual temperature changes, surface cleanliness, and moisture-proof storage. The core principle is to avoid rapid cooling/heating, strong acid/alkali corrosion, excessive clamping, and aggressive parameters to prevent micro-cracks, copper phase evaporation, or uneven structure. For electrical discharge machining, use slow parameters; for high-temperature welding, use inert gas protection; regular monitoring of loss can extend lifespan.

Usage Precautions for CTIA GROUP LTD Tungsten-Copper Electrodes

CTIA GROUP LTD Tungsten-Copper Electrode Images

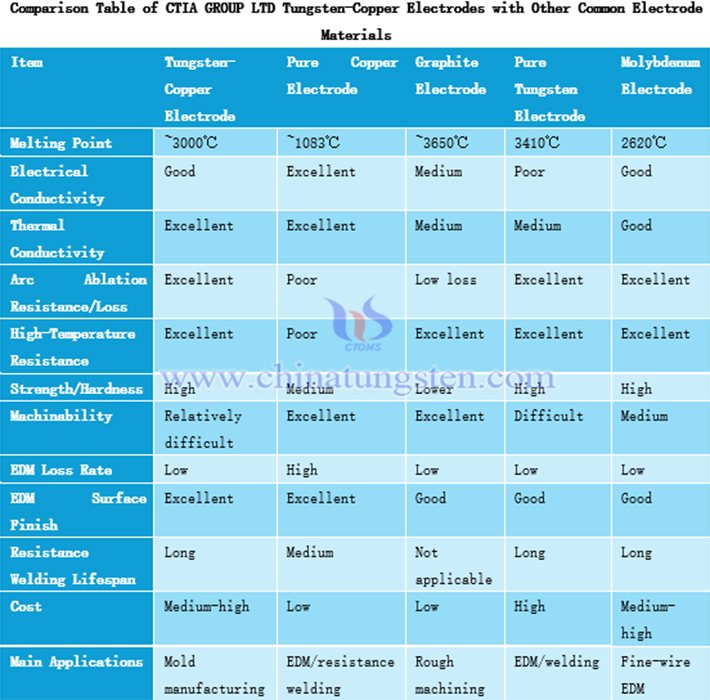

3. Comparison of Tungsten-Copper Electrodes with Other Common Electrode Materials

CTIA GROUP LTD tungsten-copper electrodes excel in arc ablation resistance, low loss, high-temperature resistance, and balanced conductivity and thermal conductivity, with overall performance superior to pure copper (prone to melting/high loss) and graphite (slightly inferior thermal conductivity, dust issues), suitable for EDM machining of hard alloys/photovoltaic semiconductor molds, new energy battery welding, high-voltage switch contacts, and other high-end scenarios. Pure tungsten/molybdenum electrodes have strong heat resistance but inferior conductivity and thermal conductivity, suitable for high-temperature or fine-wire scenarios.

Performance Comparison Table of CTIA GROUP LTD Tungsten-Copper Electrodes with Other Common Electrode Materials