The differences between CTIA GROUP LTD tungsten rubber gloves and tungsten wire woven gloves include variations in materials, protection principles, physical and chemical properties, production methods, and applications. CTIA GROUP LTD and its parent company CTIA GROUP LTD have been deeply engaged in the tungsten-molybdenum products industry for nearly 30 years, specializing in flexible customization and global services for tungsten-molybdenum products, capable of custom processing various specifications, performance, sizes, and grades of tungsten-molybdenum products according to customer needs. For more information on tungsten wire, please visit the website: http://www.tungsten.com.cn/index.html. For any tungsten rubber gloves or tungsten wire woven gloves, please contact CTIA GROUP LTD: sales@chinatungsten.com, 0592-5129595.

CTIA GROUP LTD Tungsten Rubber Gloves Images

1. Material Differences Between Tungsten Rubber Gloves and Tungsten Wire Woven Gloves

The base material of CTIA GROUP LTD tungsten rubber gloves is natural latex, nitrile, or neoprene rubber, with fine tungsten powder or tungsten compounds uniformly dispersed through high-shear mixing or dipping/coating processes, then vulcanized and cured to form a dense, pore-free elastic composite. Its protection principle is mainly based on tungsten's high density and high atomic number interacting with X-rays/γ-rays through photoelectric effect, Compton scattering, and pair production, achieving effective attenuation and absorption of ionizing radiation.

The core structure of CTIA GROUP LTD tungsten wire woven gloves is fine tungsten wire compounded with high-performance fibers (such as HPPE, aramid, Kevlar, glass fiber) through core yarn wrapping or blending, woven into a mesh fabric via warp and weft knitting. Its protection principle is mainly based on tungsten's high hardness, high strength, and the material characteristic of "hard against hard", combined with composite weaving structure to achieve cut resistance.

CTIA GROUP LTD Tungsten Rubber Gloves Images

CTIA GROUP LTD Tungsten Wire Woven Gloves Images

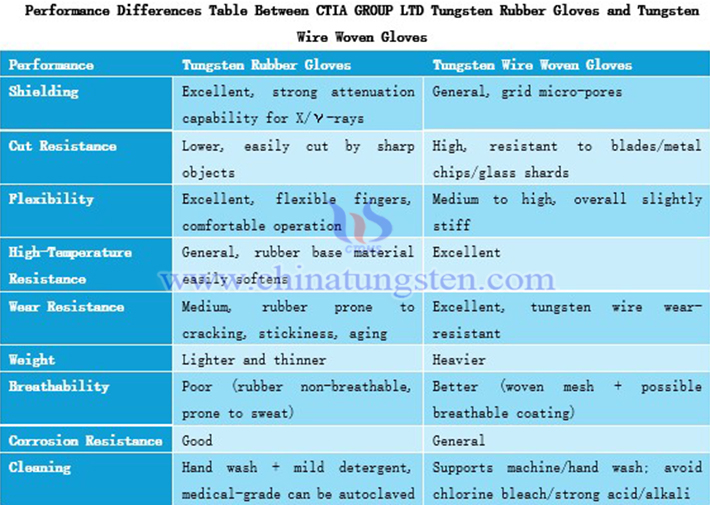

2. Performance Differences Between Tungsten Rubber Gloves and Tungsten Wire Woven Gloves

The core advantage of CTIA GROUP LTD tungsten rubber gloves lies in uniform, efficient radiation shielding and excellent flexibility and tactile feel, suitable for scenarios such as medical radiology, precision nondestructive testing, and light nuclear operations, but with weaker mechanical cut resistance, high-temperature resistance, and durability, prone to aging. Tungsten wire woven gloves, relying on tungsten wire's high hardness and toughness, achieve excellent cut resistance, high-temperature resistance, and wear resistance, suitable for industrial nondestructive testing, heavy nuclear operations, metallurgical forging, and other environments.

Performance Differences Between CTIA GROUP LTD Tungsten Rubber Gloves and Tungsten Wire Woven Gloves

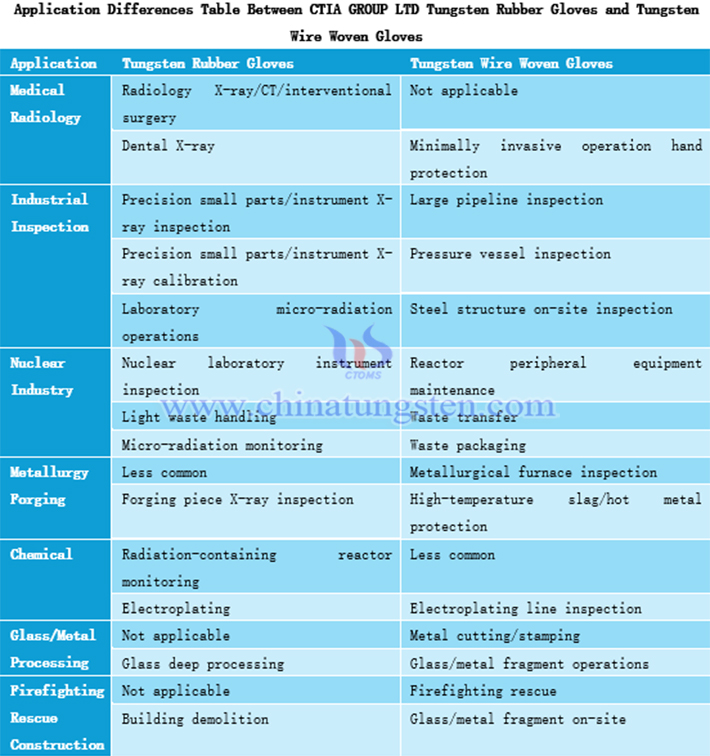

3. Application Differences Between Tungsten Rubber Gloves and Tungsten Wire Woven Gloves

CTIA GROUP LTD tungsten rubber gloves are mainly suitable for scenarios combining radiation protection with fine operations and chemical corrosion resistance, such as medical radiology departments, precision industrial nondestructive testing, light nuclear facility operations, and chemical monitoring fields. Tungsten wire woven gloves are more suitable for industrial scenarios involving high cut risk, high-temperature environments, or heavy mechanical injury, such as large structural nondestructive testing, nuclear waste transfer, metallurgical forging, glass and metal processing, and firefighting rescue operations.

Application Differences Between CTIA GROUP LTD Tungsten Rubber Gloves and Tungsten Wire Woven Gloves