The characteristics of CTIA GROUP LTD tungsten wire knitted gloves are mainly reflected in excellent mechanical protection capability, outstanding durability, good comprehensive adaptability, and reliable performance in high-risk environments.

Tungsten Wire Knitted Gloves Image

First, strong cut and puncture protection performance is the most core characteristic of tungsten wire knitted gloves. Tungsten metal possesses high hardness; when blades, glass fragments, metal sharp edges, or other sharp objects contact the glove surface, the edge finds it difficult to achieve effective penetration or continuous sliding, and instead wears down on the tungsten wire surface. This hard blocking effect reduces cutting depth, hindering the advancement process of the tool. Even when facing repeated sawing cuts, strong oblique cuts, or violent punctures, the yarn structure can still maintain integrity and continuity, without being prone to breakage or penetration. At the same time, tungsten wire has high tensile strength, capable of withstanding intense shear forces and impact loads without fracturing, thereby maintaining the stability of the overall structure under high-intensity external forces. This dual mechanism of hardness blocking and strength bearing jointly constitutes the glove's active resistance to edges and strong support from the yarn itself, providing a reliable protective barrier for the hands.

Second, durability and anti-aging performance are outstanding. Tungsten wire exhibits excellent corrosion resistance, high-temperature resistance, and fatigue resistance; in long-term contact with oil stains, chemical substances, humid environments, or repeated bending, the yarn is not prone to degradation or strength attenuation. The outer layer of high-performance fibers further enhances overall abrasion resistance and tear resistance, allowing the gloves to maintain a high protection level after high-intensity and prolonged use. Compared to traditional cut-resistant gloves, tungsten wire knitted gloves have a longer service life; even after multiple frictions, cleanings, or contacts with sharp objects, the protection performance degrades minimally, offering higher overall economy and reliability.

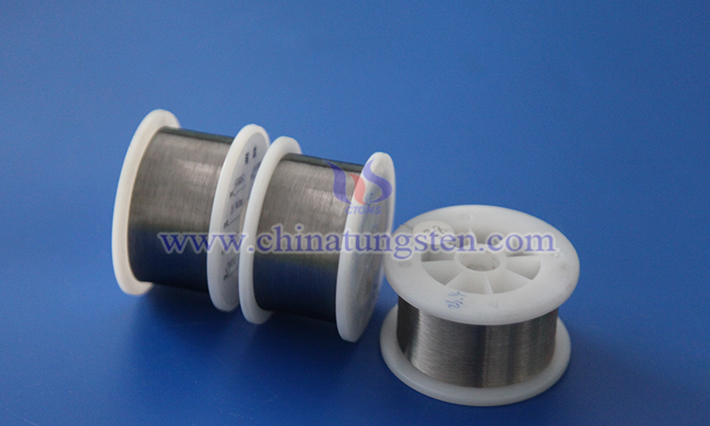

CTIA GROUP LTD Tungsten Wire Image

Third, the composite structure provides good comprehensive adaptability. Tungsten wire is typically used as the yarn core, tightly covered or co-blended with outer high-performance fibers, forming a multi-layered protection system. The outer fibers are responsible for absorbing and dispersing cutting impact energy, preventing local stress concentration from causing yarn failure; the high-density warp and weft knitting structure forces the blade to confront multiple yarns simultaneously, greatly increasing contact points and further enhancing resistance; surface coatings (such as polyurethane, latex, etc.) improve grip, anti-slip properties, and stain resistance, while generating additional frictional resistance upon blade contact, slowing sliding speed or altering cutting angle.

In addition, modern products that have undergone continuous optimization have seen significant improvements in wearing comfort. Early tungsten wire gloves might have felt stiff due to higher material rigidity, but by adopting finer tungsten wire, more flexible covering fibers, and reasonable knitting density adjustments, overall softness and fit have been improved. Finger sensitivity and tactile responsiveness are well preserved, with minimal fatigue during prolonged wear. The mesh knitting structure also imparts relatively good breathability, reducing stuffiness, making it more suitable for all-day or extended operations.