1. What Are the Uses of CTIA GROUP LTD Tungsten Alloy Rivet Bucking Bars

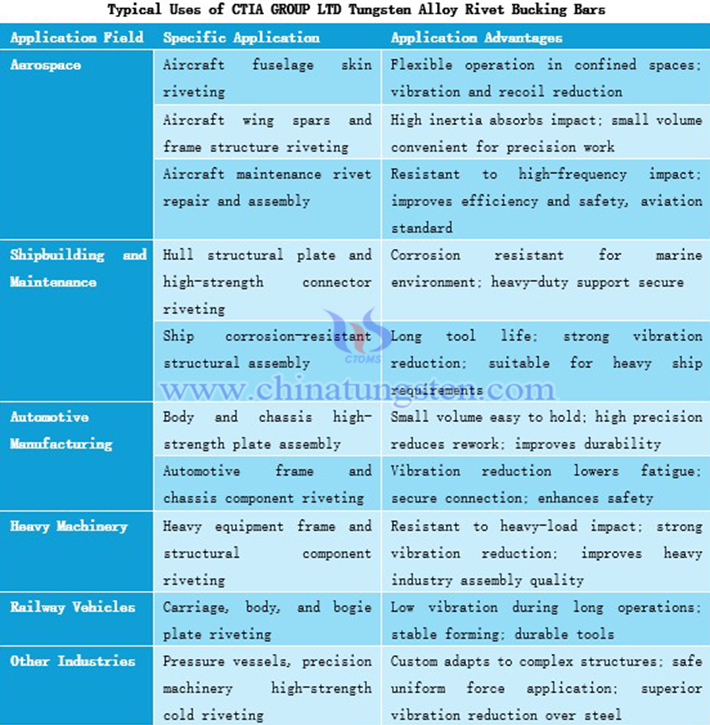

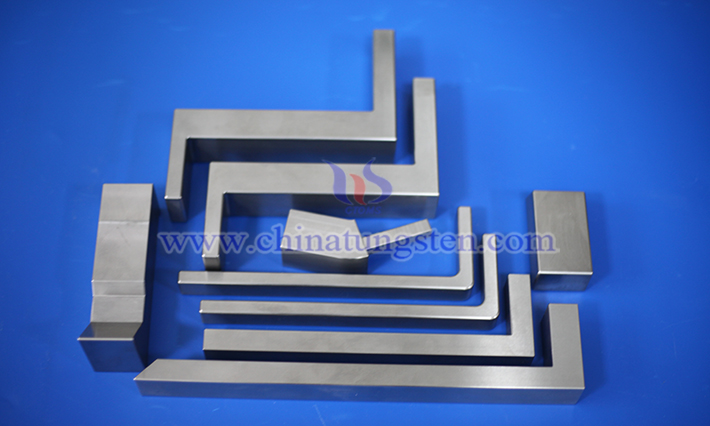

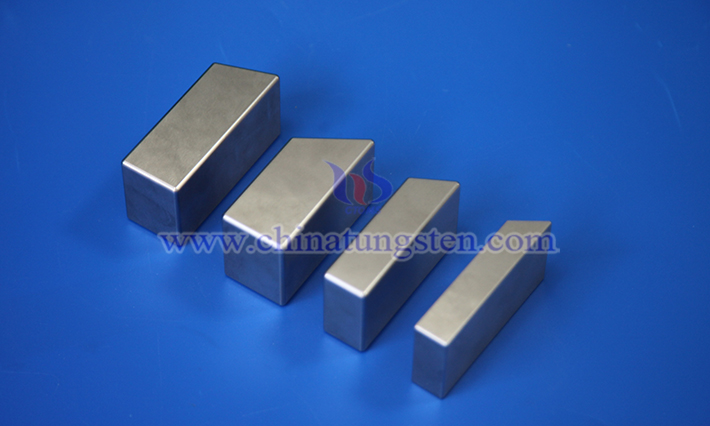

The main uses of CTIA GROUP LTD tungsten alloy rivet bucking bars (Tungsten Alloy Bucking Bar) are as reaction support tools in riveting processes, used in conjunction with rivet guns to withstand impact force, reduce vibration, and ensure high-quality rivet forming. Tungsten alloy rivet bucking bars are mainly used in high-strength cold riveting processes in fields such as aerospace, shipbuilding, automotive, heavy machinery, railway vehicles, and precision industry. With high density, excellent vibration reduction, and impact resistance, they provide strong counter support in confined spaces, significantly reducing recoil and vibration, protecting operator arm health, while ensuring uniform rivet tail forming, improving joint strength, fatigue life, and assembly quality. Tungsten alloy rivet bucking bars have become widely used key tools in aircraft fuselage skin, wing spars, and MRO maintenance; they can also significantly improve efficiency in shipbuilding, automotive, heavy structures, and other occasions.

?

CTIA GROUP LTD and its parent company CTIA GROUP LTD have been deeply engaged in the tungsten-molybdenum products industry for nearly 30 years, specializing in flexible customization and global services for tungsten-molybdenum products, capable of custom processing various specifications, performance, sizes, and grades of tungsten-molybdenum products according to customer needs. For more information on tungsten alloys, please visit the website: http://www.tungsten-alloy.com/index.htm. For any tungsten alloy rivet bucking bar products, please contact CTIA GROUP LTD: sales@chinatungsten.com, 0592-5129595.

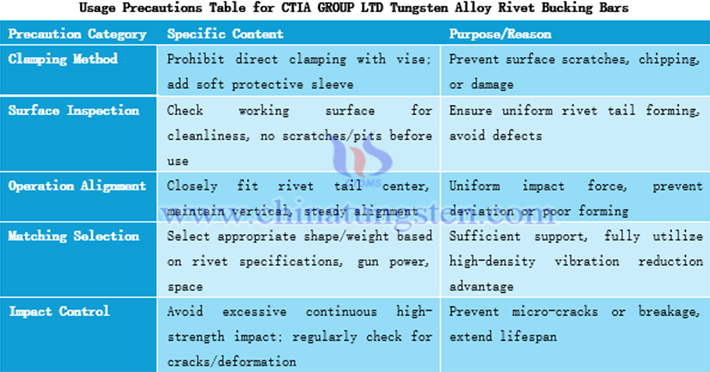

2. Usage Precautions for CTIA GROUP LTD Tungsten Alloy Rivet Bucking Bars

Usage precautions for CTIA GROUP LTD tungsten alloy rivet bucking bars include: check and protect the working surface before operation, avoid direct clamping or collision; hold steadily and align properly, match appropriate specifications; control impact strength, regularly check for cracks.

3. Performance Comparison of CTIA GROUP LTD Tungsten Alloy Rivet Bucking Bars with Steel Rivet Bucking Bars

Compared to steel bucking bars, CTIA GROUP LTD tungsten alloy rivet bucking bars have a density of 17–19 g/cm3 (approximately twice that of steel), providing higher inertia and smaller volume. In riveting, they significantly improve impact energy absorption efficiency, reduce recoil and vibration transmission, decrease arm fatigue and vibration-related occupational hazards. At the same time, they enable precise operation in narrow spaces (such as aviation structures). In addition, tungsten alloy rivet bucking bars also feature high hardness, excellent toughness, resistance to high-frequency impact, and corrosion resistance.