Tungsten balls for sealing valves are typically hard alloy balls sintered from high-hardness metal carbides such as tungsten carbide (WC) as the matrix and cobalt (Co) or nickel (Ni) as the binder. They possess high hardness, wear resistance, corrosion resistance, impact resistance, high-precision sealing, and self-lubrication properties, making them a core component for achieving reliable sealing in sealing valves.

I. Core Characteristics of Tungsten Balls for Sealing Valves

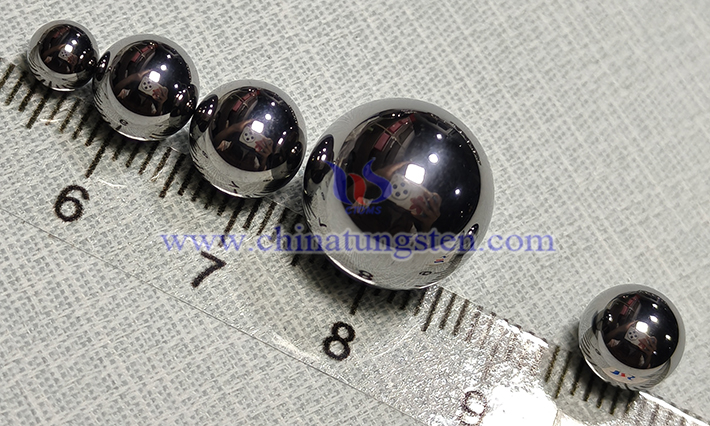

1.1 High Hardness and Wear Resistance: The hardness of tungsten balls typically reaches HRA 90 or higher (approximately HV 1500-1800), far exceeding that of ordinary steel balls (HRC 40-55). Their microstructure consists of dense carbide particles, effectively resisting the cutting and wear of hard particles such as coal slurry and mineral powder, extending the service life of sealing valves.

1.2 Corrosion Resistance: In strong acid, strong alkali, or saline media, tungsten beads exhibit significantly better chemical stability than ordinary steel beads, maintaining stable sealing performance and reducing the risk of leakage.

1.3 Impact and Bending Resistance: Tungsten beads can withstand impact loads under high pressure, high temperature, and high speed conditions without easily deforming or breaking, ensuring reliable sealing.

1.4 High-Precision Sealing: The high surface smoothness of tungsten beads allows for complete contact with the sealing surface, achieving zero-leakage sealing, especially suitable for high-pressure, high-temperature, or highly corrosive environments.

1.5 Self-Lubricating Properties: The low coefficient of friction between tungsten beads and the sealing surface reduces energy loss, eliminating the need for additional lubricants and lowering maintenance costs.

II. Application Scenarios of Tungsten Beads for Sealing Valves

2.1 Oil and Gas Industry: Used in wellhead valves, pipeline valves, etc., to resist the erosion of sand-containing and corrosive media.

2.2 Chemical Industry: Tungsten bead sealing valves can operate stably for long periods in highly corrosive media such as sulfuric acid and hydrochloric acid.

2.3 Power Industry: In high-temperature and high-pressure steam pipeline valves, the high-temperature resistance of tungsten beads ensures sealing safety.

2.4 Water Treatment Industry: In seawater desalination, sewage treatment, and other applications, the corrosion resistance of tungsten beads extends valve life.